Panasonic EYC159LR Cordless, Battery Powered, Rechargeable 18V Hammer Drill Driver / Impact Driver Combo

Construction professionals that drill holes and drive fasteners into wood, metal or concrete and also do repetitive bolt/nut fastening, scaffold assembly/disassembly and lag bolt driving need the versatility of a cordless hammer drill and the adjustable power of an impact driver.

The 18-volt EYC159LR packages that versatility into one kit. The 1/2" EY7950X hammer drill and driver and the EY7550X impact driver stand at the ready to complete a variety of heavy-duty jobs that electricians, general construction contractors, system installers, heating, water and sanitation technicians can throw at them.

Whether it's masonry, metal or wood drilling or fastening, the EY7950X hammer drill, at only 5 lbs. with the battery, is easy to use in overhead or far-reaching applications.

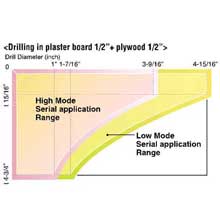

At only 9-1/4" long x 9-3/4" tall x 2-1/2" wide, the compact hammer drill delivers 478 in.-lbs. of torque. It can drill up to 1/2" diameter holes in metal or masonry or up to 1-7/16" diameter holes in wood. The two-speed transmission produces 50-430 rpm/900-7,740 bpm in low speed and 160-1,650 rpm/2,800-29,700 bpm in high speed. The variable speed and reversible tool has the power to efficiently drive up to 5/16" diameter wood screws and up to 1/4"-diameter self-drilling metal screws.

The 1/2" metal heavy-duty keyless chuck allows easy bit changes, yet holds the bit firmly during drilling, hammer drilling and fastening. An electric brake stops the bit immediately when the trigger is released and an LED light illuminates the work area for accurate drilling or fastening.

Workers can select one of 18 clutch settings, which steps up torque in 3.0 in. lbs. increments from 8.8 to 61 in. lbs., so users can match torque to fastener/driving needs.

Professional tradesmen often do a wide variety of highly repetitive fastening jobs, and the EY7550X 1/4" hex cordless impact driver kit has the versatility, power and runtime to excel in heavy driving, demanding fastening or exacting finish-assembly applications. The cordless impact driver has variable speed and three power settings that make it handy for heavy-power or fine-control jobs such as HVAC installation, auto repair, deck building, lag bolt or finish fastening and more.

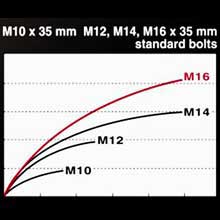

The High/Hard setting is best for heavy driving jobs such as setting lag bolts, tightening large bolts and nuts or driving long screws. In this setting, it delivers 0-2,500 no-load rpm, 1,370 in.-lbs. of torque and 0-3,000 ipm. The Medium setting is suited for driving self-tapping screws and conduit clip fasteners, delivering 0-1,400 no-load rpm, 1,150 in. lbs. of torque and 0-2,800 ipm. For delicate fastening jobs that require controlled power and finesse, such as installing hinges on cabinets and fastening wall plates to electrical boxes, the Low/Soft setting delivers 0-1,000 rpm, 355 in. lbs. of torque and 0-2,000 ipm.

An electric brake stops the 1/4" hex quick-connect bit instantly in all modes; a built-in LED light greatly improves work visibility. Weighing just 3.5 lbs. with battery, the compact tool measures just 2-13/32" wide, 9-17/32" tall and 5-5/8" long. A convenient built-in belt hook keeps the driver handy.

Both the hammer drill and impact driver are powered and controlled by a brushless motor, durable switch and sealed control circuits in the tool body and battery pack. These high-tech and resilient systems deliver top power, speed, runtime and long tool life. Because electronics replace brushes in the tool, the tool creates less heat and uses power much more efficiently than conventional motors found in many cordless tools. That means longer runtimes between charges, cooler operation and longer tool and battery life. Their design also allows them to operate under substantial loads, making it less likely to burn out when used for heavy-duty jobs.

The cordless hammer drill/driver and impact driver kit comes with two Panasonic 18-volt 3.3Ah LR Li-ion battery packs that are built for heavy use, long runtimes between charges and long cycle life. Unlike manganese-based Li-ion batteries used in many cordless power tools, Panasonic's exclusive cobalt Li-ion battery technology produces less internal heat buildup that can kill battery packs. The battery packs also feature Panasonic's Solid Solution technology, a proprietary process for dissolving and hardening cobalt and nickel and other key battery components. This unique chemistry dramatically improves battery pack safety, reliability and power output. A special heat-resistant ceramic coating layer separates cells and protects them from heat buildup. The chemistry, battery design and manufacturing process add up to powerful batteries that promise to deliver long running lives.

Sometimes professional users are their own tool's worst enemy, attempting to push them past their design limits. This can lead to irreversible battery or tool damage. That's why Panasonic 3.3Ah LR battery pack cells are independently monitored for even discharge while preventing over-charging and over-discharging. An over-discharge sensor prevents the user from running the tool after it reaches the point where too-low voltage output could damage the battery and the tool. Plus, an internal temperature sensor flashes a warning light if internal temperatures rise, and then cuts off tool power if battery temperature reaches critical levels.

Getting water into the battery doesn't have to mean it's a goner. Panasonic engineers have added built-in vents in the battery case so water can easily drain out of the battery pack. The battery, which is easy to remove using a simple slide-down release button, charge to 80 percent capacity in 50 minutes and fully charge in 65 minutes with the EY0L81B charger that comes with the kit.

Â Â

The EY7950X hammer drill and driver and EY7550X impact driver have an IP56 rating that proves the tools' toughness claims. This rating means the tools have withstood demanding laboratory tests of working in extremely dusty work environments and the effects of water getting sprayed on the tool by powerful jets. In the field, it assures professional tradesmen have tools that can stand up to the rigors of hard jobsite use.

The IP rating is established by the International Electrotechnical Commission (IEC) and is outlined in IEC 60529. The standard outlines a coding system that indicates the degree of protection an electrical machine's enclosure offers internal components. Based on objective testing, it assigns a rating to the enclosure's ability to keep potentially damaging solid foreign objects (dust and contaminants) and water out of the tool under increasingly difficult conditions.

The dust protection test subjects the tool to a very dusty environment and then puts it to work to assure the tool was unaffected by dust exposure. In the grueling test, the tools proved that they achieved a dust protection level of five out of six levels; the sixth level is for dust-tight tools. It's a good indication that the tool's design keeps potentially harmful contaminants out, assuring long life and top performance that professionals demand.

Similarly, the water protection test put the tools up against increasing levels of water exposure. They attained a six out of eight levels rating, withstanding the effects of powerful water jets.

Whether it's extremely dusty work conditions or work in damp or wet locations, users will appreciate a tool that will keep working when others would likely fail. Consult the safety and operating instructions for more information.